Every minute and every order counts in the world of secondhand retail.

Manual picking slows teams down, invites costly errors, and makes multi-item fulfillment a challenge.

Upright’s Digital Picking, available through Lister and Link Mobile, changes that. It’s a faster way to pick and fulfill orders with precision and ease. As Adam Kragt, Upright’s Professional Services Specialist, puts it: “With custom filters and barcode scanning, teams can save hours a day while increasing picking accuracy.”

What is Digital Picking?

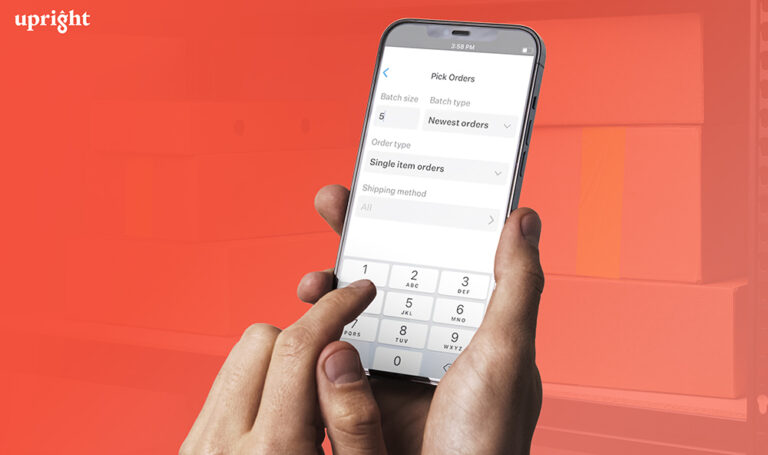

Digital picking is a streamlined, customizable way to identify and fulfill customer orders directly from your inventory. Instead of juggling spreadsheets or paper pick lists, your team can work entirely within Upright Lister and the Link mobile app, creating clear, guided workflows that adapt to your business needs.

Digital picking helps turn fulfillment from a daily bottleneck into a well-oiled, data-driven process. With the proper setup, you’ll see faster fulfillment times, fewer errors, and measurable time savings across every pick list. The benefits add up quickly:

- Custom pick filters and profiles save hours per day by removing manual setup.

- Barcode scanning improves accuracy and reduces mispicks.

Optimized inventory location naming cuts travel time and keeps your warehouse running smoothly.

Setting Up for Success: Filters, Statuses, and Predefined Profiles

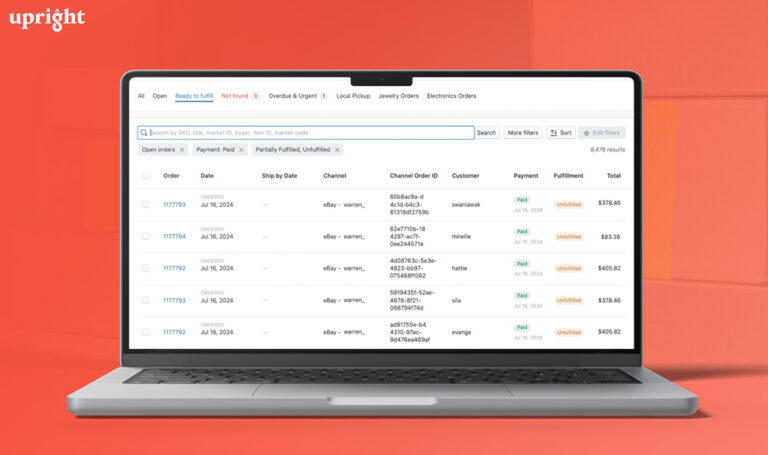

Every efficient fulfillment process starts with clarity, and Upright provides it from the outset. Within Lister, your orders are automatically organized through a system of statuses and filters that help your team focus only on what’s ready to be picked.

- Order statuses: Open, canceled, or archived, so you never waste time on orders that are already closed or invalid.

- Fulfillment statuses: Unfulfilled or fulfilled to show exactly what still needs action.

- Pick & pack statuses: Locked or unlocked to prevent duplication and keep active batches clear.

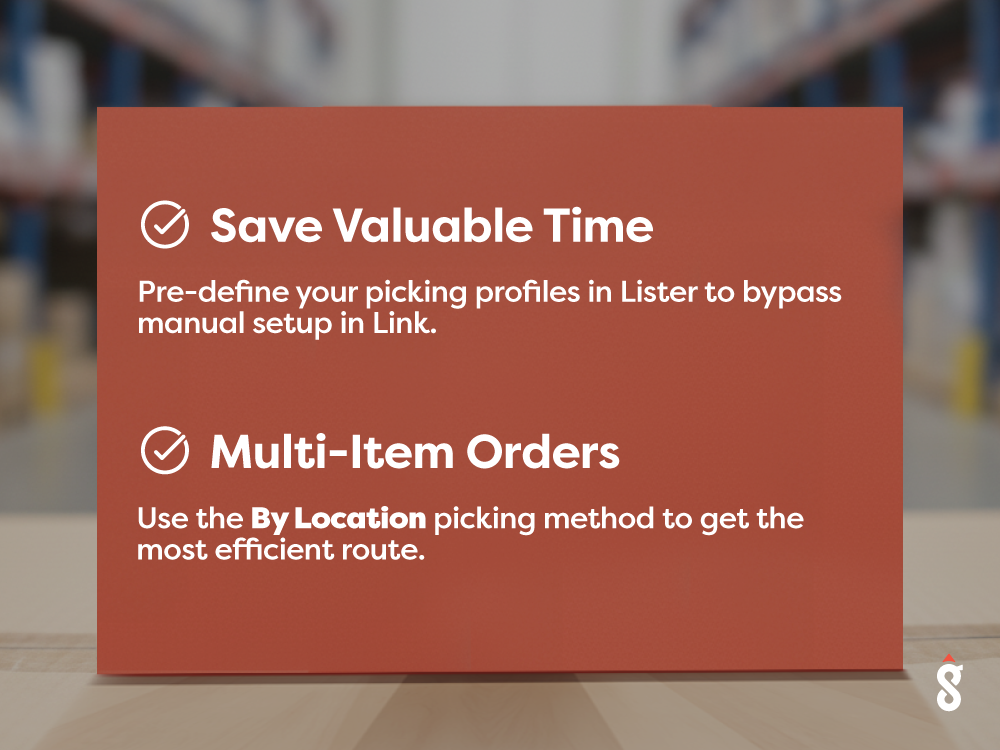

With these statuses in place, your team can ensure only valid, ready-to-pick orders are included in each list. The real time-saver, though, is predefined picking profiles in Lister. Whether your team is focused on books, media, or apparel, you can pre-set every filter they need once and reuse it daily.

In our recent Master Class on Digital Picking, Adam Kragt mentions, “Defining your picking profiles once saves staff valuable time if they’re picking multiple times per day, as they don’t have to redefine their filters each time they need to pick items.” It’s one of those small operational changes that quickly adds up to hours saved each week.

How Upright’s Digital Picking System Works

Upright’s digital picking process is designed to make fulfillment faster, smarter, and more scalable, without adding complexity. Here’s how it works in practice:

- Identify open, unfulfilled, and unlocked orders.

Lister automatically filters out completed or restricted orders so your team focuses only on what’s ready to ship. - Apply targeting filters.

Select filters by sales channel, order type, date range, or payment status to focus on priority batches or specific workflows. - Sort by batch type.

Organize picks by payment date or ship-by date to ensure the most time-sensitive orders are fulfilled first. - Limit by item count or bin count.

Match pick list size to your warehouse capacity and cart size. Keeping lists manageable ensures faster picking and prevents bottlenecks. - Generate optimized pick lists.

With a single click, Lister and Link create smart pick lists tailored to your layout and staff flow. Each list guides your team through the most efficient route, reducing travel time, confusion, and fatigue.

The result is a streamlined fulfillment system that seamlessly combines accuracy, speed, and scalability. Whether you’re managing hundreds of single-item orders or complex multi-SKU batches, Upright’s Digital Picking keeps your team organized and your customers satisfied.

Picking Strategies That Boost Efficiency

No two warehouses are exactly alike, which is why Upright gives you flexible ways to organize your picking strategy. The system supports two main methods:

- By order: Items are grouped by order, best suited for situations where each order requires individual handling. However, many teams find the “By location” option more efficient once their process is established.

- By location: Items are organized by their physical warehouse location, enabling pickers to follow the most efficient route possible.

Choosing “By location” minimizes backtracking, reduces walking distance, and increases throughput. For high-volume resale operations, this can save hours each week and keep fulfillment running smoothly even as order volume spikes.

Extra Tip!

Choose your picking method based on your space and staff flow. Upright gives you the flexibility to work your way. Whether you’re optimizing for team size, product type, or layout, the system adapts to your workflow instead of forcing you into rigid rules.

Advanced Tools: Multi-Order Picking and Specialty Lists

Upright’s Digital Picking tools also make it easy to handle complex workflows like multi-item or category-specific orders.

Multi-Order Item Picking

Instead of generating separate pick lists for every order type, Upright lets you combine single- and multi-item orders into one efficient list. This reduces the total number of lists your team handles, saves setup time, and improves coordination across shifts.

As our Professional Services Specialist at Upright Labs explains: “Multi-order picking gives teams the flexibility to pick both single and multi-item orders at once, cutting down the total number of pick lists and improving overall throughput.”

The result is faster picking, fewer pauses, and a smoother handoff between staff.

Specialty Pick Lists

Every resale business has unique categories, such as books, jewelry, media, and apparel, and Upright makes it easy to tailor pick lists to those specific needs. You can filter by category, location, or other attributes to create focused lists that align with specialized workflows.

Just remember, when dividing picking responsibilities by category or product type, it’s crucial to maintain fulfillment integrity. Ensure that each picker completes their list fully before exiting the picking process to avoid duplicate work or incomplete orders. Upright’s locking system helps safeguard this process automatically.

Turn Every Pick Into a Competitive Advantage

Great fulfillment hinges on three key factors:

- Speed

- Accuracy

- Visibility

Upright’s Digital Picking delivers all three, giving resellers the tools to move faster, minimize errors, and keep every order on track.

Built specifically for the resale industry, Upright combines intuitive software with expert support from people who understand your day-to-day challenges. And because the platform continually evolves with real user feedback, it keeps getting smarter, helping you stay one step ahead as your business grows.

If you’re already using Upright Lister and Link, reach out to your Account Manager to learn how Digital Picking can elevate your workflow.

If you’re getting started in selling online or exploring new e-commerce solutions, contact our Growth Team to see Upright Lister in action.