After optimizing the flow for 30+ e-commerce fulfillment and processing centers, each of which manages over 250,000 packages per month, the Upright Labs team wanted to share inventory storage best practices, particularly for secondhand items.

Optimizing your warehouse flow begins with prioritizing good design. When designing your fulfillment center’ s inventory management system, you should focus on three things:

- Reducing time spent handling products and number of times touching products

- Minimizing time from purchase to outbound shipment

- Ensuring the right item reaches the right customer, without damage

Below you’ll find our top best practices and recommendations when it comes to warehouse design.

Warehouse Design Best Practices

Tip #1: Incorporate Scannable Barcodes

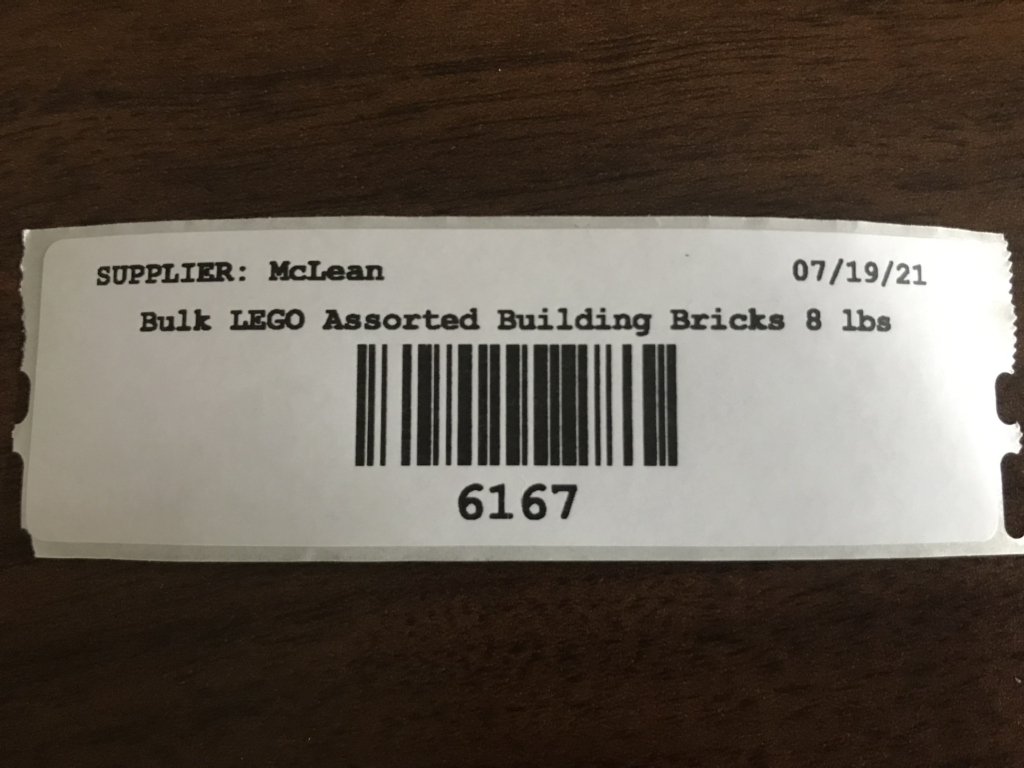

Before designing your new fulfillment center, it is important to ensure every product has a unique SKU (Stock Keeping Unit, a code used to identify unique items). Using SKUs goes hand in hand with design and will make completing tasks easier for any stakeholder involved in your day-to-day operations.

You should have SKUs for every single item flowing through your warehouse. Even if you carry multiple units of the same product, attaching unique SKUs to each of those units is critical for maintaining the location of all of your items. It is also important to note the SKUs you attach to in-warehouse items will be for warehouse purposes only, and will not represent the products’ original manufacturer or retailer.

In addition to unique product SKUs, each inventory location should have a scannable barcode. This allows for more efficient and accurate inventory management workflows like item putaway and picking. When an item is ready to switch locations, you should use your inventory management software to scan the item SKU and then the location barcode. Scanning both the item and its location will ensure you and your employees know where every item in your fulfillment center is located and who last touched an item.

If your items go through other touchpoints before being placed in their end location, be sure to barcode those locations as well. Whether the touchpoint is a cart or another area in the warehouse, barcoding these points is essential for preventing item misplacement and overall efficiency.

The following best practices pertain to how to name and label your inventory locations.

Tip #2: Use Numbers Not Letters

Location barcodes should use numbers rather than letters. Using letters in fulfillment can increase the time needed to find items by forcing the employee to recite the alphabet to figure out which letter comes next and to determine which direction they should go in your warehouse. Ultimately, it’s easier to remember that 7 comes before 10 than it is to remember that G comes before J! Additionally, letters will cap you at 26 where numbers can continue increasing beyond that and account for larger warehouse spaces.

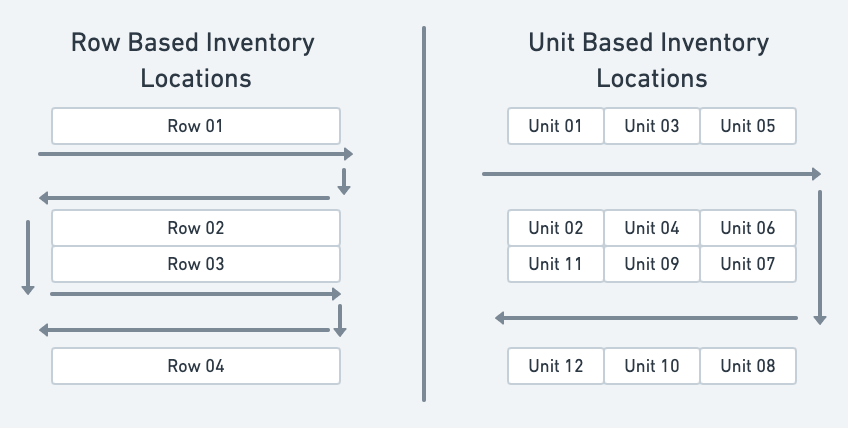

Tip #3: Start with Units Not Rows

Instead of operating off of rows then units, a more streamlined approach will use the shelving unit as the first indicator of location. This ensures that as a picker is walking down an aisle they can grab items from both sides of the aisle rather than going all the way down the aisle then walking back up the same aisle. This simple change can reduce a significant amount of unnecessary steps!

Tip #4: Use Highly Specific Locations

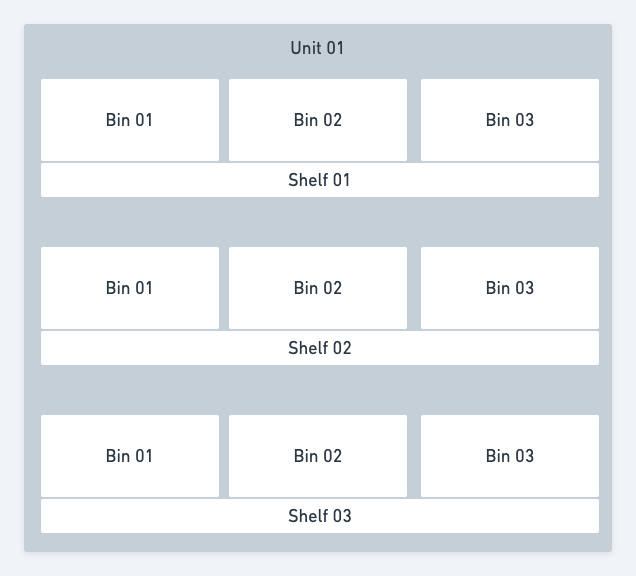

To help your team find items efficiently, we recommend getting as granular as possible with your locations. The more specific the location, the easier it will be to locate the item. In addition to the unit number, the inventory location should identify the exact shelf location and bin number (if applicable).

Storing in clear or cardboard bins is great for items smaller than 144 cubic inches (12 in x 12 in x 12 in). Each bin would represent an individual inventory location capable of holding multiple items. Some items like bulky art or musical instruments may not fit in bins. In those cases, the best approach is to have some shelves without bins and label those shelves as individual locations.

To distinguish between bins, the naming convention would start with the unit number, then the shelf number, then the bin number. The end result might look something like Unit 01 Shelf 03 Bin 03.

Tip #5: Directionality

To further expedite your inventory management activities, shelves and bins should be labeled according to the direction in which people read. In English and other Latin based languages, people read left to right. With that in mind, facilities that operate in those languages should label shelves in ascending order top to bottom and label bins in ascending order left to right. If your warehouse is in a country where people read right to left, however, place Bin 01 in the top right of your shelves.

Conclusion

Warehouse design is a key lever in streamlining your product flow and operational processes. By incorporating barcoding into your operation and designing inventory locations that are intuitive, organized, and easy to maneuver you can spend less time finding items and more time selling them!

Upright Labs provides multi-channel listing and inventory management software for power resellers. Use our cloud-based software to list to multiple resale platforms with one form, fulfill and ship orders in 2 clicks, leverage multi-carrier shipping, visualize top KPIs in pre-built dashboards, track inventory and employee touchpoints, save 30-50% of photography time for each listing with our mobile app, and so much more.